Do you want to access to this and other private contents?

Log in if you are a subscriber or click here to request service

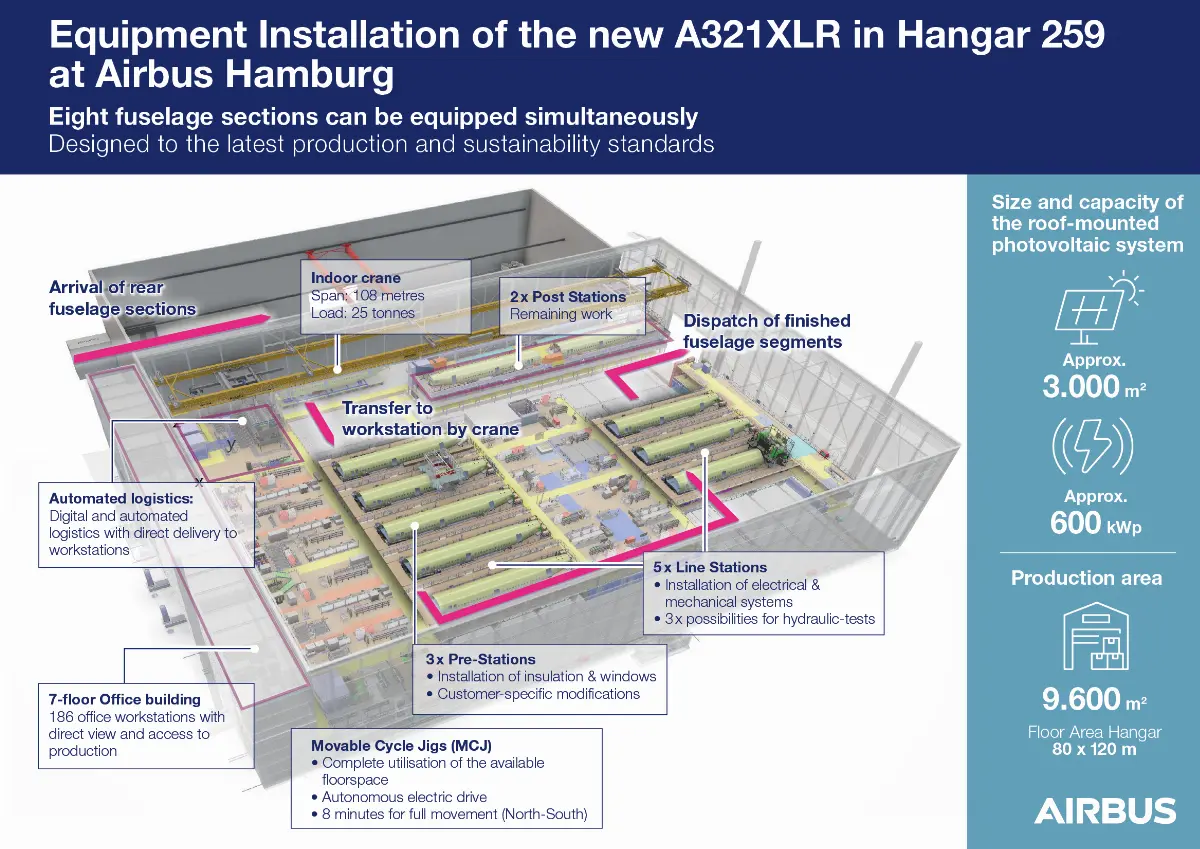

Airbus: new hangar inaugurated in Hamburg

Dedicated to the A-321XLR aircraft equipment installation

Airbus is advancing its industrial system and expanding ramp-up capacity with a new automated A-321XLR equipping hangar, officially opened yesterday by Hamburg’s First Mayor Peter Tschentscher and German Aerospace Coordinator Anna Christmann. With this, the company continues its modernisation and digitalisation of its industrial system and expands its capacity for the rate ramp-up in the A-320 programme t...

red/f - 1253400

AVIONEWS - World Aeronautical Press Agency

AVIONEWS - World Aeronautical Press Agency